It's another kind of imagination manifest. Just like the bug that got me in to writing software, you know, the "OMG I can make this thing do whatever I can imagine?" kind of feeling. But now with physical objects too. Even mechanical parts that move. I find myself designing little hardware bits that are exactly what I want instead of trying to make do with stuff that already exists.

I started off by resurrecting an old Cupcake CNC, which never printed anything without issue. I replaced the electronics for about $30 so that I could load modern firmware, and replaced the ill-fated DC motor extruder with $40 thing from China. It worked! I could now actually print something, but the mechanics were so sloppy that the quality was pretty rough. Good enough for structural parts, but not fitted designs.

So I went researching and shopping around. I didn't plan on spending a lot, but didn't need much either. I found the Monoprice Maker Select v2. For something in the $350 range, it has impressive specs, and nice build quality.

Sort of.

Of the two that have arrived in working form, two have experienced power-heat related issues. The first manifested itself as "crashing" during printing, that turned out to be an issue with the power connector overheating. Turning it off and on again worked, until part way through the next print. I got it RMA'd and the replacement arrived only a few weeks ago and had printed several things successfully.

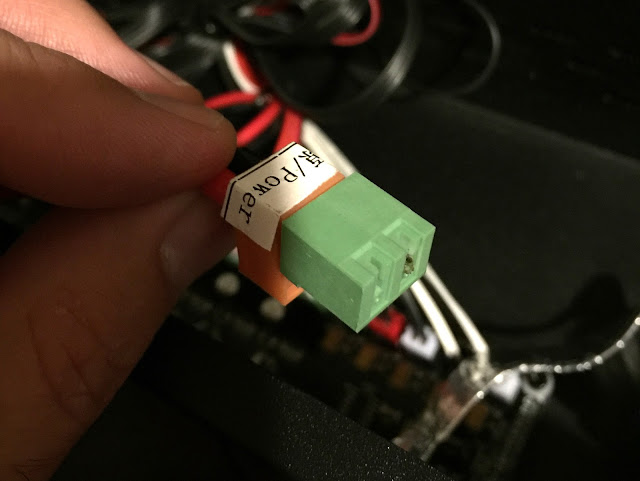

Here's the first connector heat failure, which I thought was just a fluke:

I went through Monoprice's support without much fuss. They aren't that fast, and you can expect 24-hour turnarounds with several back-and-forth questions, but ultimately they RMA'd the printer and shipped out a replacement.

I had the replacement for a few weeks, when last Friday the replacement nearly caught on fire while preheating.

This wasn't a "poof" the magic smoke escaped from some chip somewhere, this was going strong and getting worse by the time I got to it and cut power. There was a lot of smoke.

Elecia of embedded.fm helped do an autopsy and capture some charred board pictures.

|

| Slight browning of PCB and compo |

|

| Blackend power connector (middle right), also weird looking solder joint on hotbed connector (middle left) |

|

| The capacitor is hiding the crater |

|

| After removing the power connectors, you can see the crater more easily. Charred bits and exposed copper. |

So obviously the next step is to power it back on and see if it still works. We left the hotbed disconnected since it had more damage. There was a bit of a spark and a poof of smoke which seemed to "blow" the short and let the board boot up.

Yeah, I wouldn't leave it unattended.

I only have a sample size of two, but clearly there is some design or component flaw that is a real fire risk and Monoprice is still shipping (as of a few weeks ago) printers with this design.

Monoprice (and perhaps Wanhao the OEM) should recall these printers.

Despite the frequent setbacks, 3D printing has become an invaluable tool.

I'm not really sure where to go from here. I might be able to RMA this and get another printer, but there's no way I'd run this model in my house again.

The mechanical parts of the printer has worked very well for me (XYZ and extruder). Maybe I can gut the electronics, replacing it with something reprap?

Maybe they will refund it? Officially they have a 30 day refund policy which is expired even if you only count the total days both printers were running. I'd rather put the money toward a different printer, perhaps a genuine i3.